Capacity Planning Formula in BPO for Marketing Agencies

Share now

Most agency owners sell to the capacity of their team and then break a sweat when they have to fill in the talent gaps. This is similar to trying to scale a river without widening the banks, but what can you do when the alternative is overhiering and eating the cost internally.

The capacity planning formula in BPO (Business Process Outsourcing) is not just a theoretical concept for manufacturers; it is the single most critical operational formula for any agency owner looking to scale past seven figures. It’s the math that reveals your true growth bottleneck.

At 8 Figure Agency, we don't just talk about capacity; we build the systems that make it scalable. Our team has helped agencies generate over $500M in recurring revenue by systemizing operations. We are experts in translating the complex BPO capacity formula into a simple, actionable dashboard that gives you total clarity on what to tackle next.

In this post, let’s dive into the capacity formulaor the capacity utilization rate to help you maintain peak productivity and scale your business to 8-figure success.

What is a Capacity Planning Formula?

At its core, capacity refers to the maximum potential of a system to produce or deliver. Whether it’s the number of products manufactured, clients served, or tasks completed, capacity signifies the upper limit of what’s achievable. However, it’s crucial to note that capacity isn’t just a static number; it’s a dynamic concept that can be fine-tuned and optimized.

In the agency world, capacity is the maximum number of clients you can successfully onboard and fulfill without sacrificing quality, burning out your team, or spiking your churn rate.

If your sales team is closing 20 new clients a month, but your operations can only handle 12, your operations are your bottleneck. Quality drops, churn spikes, and your MRR ceiling drops.

To break that ceiling, you need to stop guessing what your capacity is and start using the math.

Factors Affecting Capacity: Balancing the Formula

Capacity isn’t a solitary number ; it’s influenced by a multitude of factors. From physical resources like machinery and workforce to intangibles like expertise and time, a delicate equilibrium must be maintained.

External factors such as market demand, technology, and even regulatory constraints further impact the capacity formula, making it a nuanced dance of variables.

The Capacity Formula in Operations Management

Every production process is a masterpiece in the making. The capacity formula acts as the guide, ensuring that the factors of time, labor, and materials converge harmoniously to create the final product. By embracing the capacity equation, business and agency operations managers can fine-tune processes to eliminate waste and inefficiencies.

Utilization is the heartbeat of capacity—how effectively are you putting your resources to work? Optimizing utilization ensures that every resource is contributing to overall productivity, preventing waste and bottlenecks.

The core of capacity planning is the Capacity Utilization Formula. It’s a simple, brutal metric that tells you exactly how efficiently you are using your resources.

How to Calculate Capacity for Optimal ROI

Calculating capacity isn’t a mere mathematical exercise; it’s an art of understanding and synthesis. By factoring in the resources available and their efficiency you can arrive at a comprehensive understanding of your capacity. This capacity calculus isn’t a one-size-fits-all affair; it’s tailored to every unique situation.

Capacity Utilization Formula = (Actual Output/ Potential Output) x 100

- Actual Output : This parameter represents the real, tangible production or output that an organization has achieved within a specific timeframe. It reflects the actual quantity of products produced, services rendered, or tasks completed.

- Potential Output: Potential output is the theoretical maximum production that could be achieved under ideal conditions. It represents what the organization could produce if all resources were fully utilized, processes were operating optimally, and there were no constraints or disruptions.

Here’s an example to illustrate the concept:

Suppose a manufacturing company produces 800 units of a product in a month. However, based on its production capacity and ideal conditions, it could potentially produce 1,000 units in the same time frame.

- Actual Output : 800 units

- Potential Output : 1,000 units

Now let’s plug these values into the formula:

Capacity Utilization = (800 / 1,000) x 100 = 80%

In this example, the company’s capacity utilization is calculated to be 80%. This means that the company is operating at 80% of its maximum potential output. The remaining 20% represents the untapped capacity that could be utilized by improving processes, increasing efficiency, or allocating resources more effectively.

A high capacity utilization percentage, such as 90% or above, indicates that the organization is efficiently using its resources and is close to operating at its full capacity. On the other hand, a low percentage might suggest inefficiencies, underutilization of resources, or factors limiting production.

It’s important to note that capacity utilization can vary based on factors like seasonality, demand fluctuations, maintenance schedules, and unexpected disruptions. Monitoring and analyzing capacity utilization over time can help organizations make informed decisions about resource allocation, production planning, and process improvements.

The best BPO Capacity Planning Formula for Marketing Agencies

The BPO (Business Process Outsourcing) model is built on predictable, repeatable processes. Agencies must adopt this mindset. The formula for an 8-figure agency is not just about utilization; it’s about linking capacity to your financial reality.

As we discuss in our 13 Core Systems, your growth is governed by the MRR Cap Equation:

\text{MRR Ceiling} = \frac{\text{New Monthly Revenue}}{\text{Monthly Churn Rate}}

You can push sales harder, but until you fix your operational capacity (which directly impacts your churn rate), you will never break past that ceiling.

Capacity planning for agencies is the art of ensuring your operational capacity (fulfillment and onboarding) always outpaces your sales capacity (new monthly revenue).

Capacity planning is the North Star for businesses seeking to navigate the turbulent waters of growth and market fluctuations. It involves projecting future demand, assessing existing resources, and aligning these elements to ensure that an organization is prepared to meet customer needs while avoiding bottlenecks or under-utilization.

Imagine a retail business gearing up for the holiday season. By employing the capacity formula, the business can estimate the expected increase in demand, adjust inventory levels, and ensure a sufficient and high-performing team to handle the surge in customer activity. Capacity planning is essentially the art of foresight—anticipating demand and optimizing resources to capitalize on opportunities.

Capacity Planning in Marketing Industries

Capacity planning in services is all about matching resources to demand. In the marketing industry, for instance, a marketing agency can use the capacity formula to strategically allocate its creative and analytical talents to various projects. Just as a hotel aims to ensure each guest receives exceptional service during peak season, a marketing agency strives to deliver winning marketing proposals , compelling campaigns, tailored strategies, and impactful results to its clients.

Consider the launch of a new product by a client company. The marketing agency can leverage the capacity formula to determine the optimal allocation of its experts, from graphic designers and content creators to digital strategists and data analysts. By ensuring that the right mix of talents is assigned to the project, the agency can meet tight deadlines, maintain consistent quality, and provide valuable insights to the client.

Furthermore, capacity planning within the marketing industry extends beyond just human resources. It involves anticipating surges in demand for various marketing services, such as social media management, SEO optimization, and content creation. By analyzing historical data and industry trends, the agency can align its team , resources and service offerings with the evolving needs of its clients.

Capacity Planning and How it Affects Projects

Whether the case is a digital product or SEO content plan, capacity planning prevents resource shortages and timeline delays.

Consider a software development project with a fixed deadline. By applying the capacity formula, project managers can allocate tasks based on resource availability, preventing overburdening of team members and potential bottlenecks. It’s a proactive approach that enhances project efficiency and client satisfaction .

Our services aren’t just about growth; they’re about refining operations, streamlining fulfillment processes, and enhancing overall management efficiency. If you’re looking to elevate your agency to 8-figure success, our tailored solutions are designed to guide you toward excellence.

Resource Allocation for Marketing Agencies

Resources are the fuel that powers the engine of productivity. Proper allocation ensures that no resource goes underutilized or overburdened. The capacity formula guides resource allocation, ensuring a delicate equilibrium that leads to smooth operations and optimal output.

Imagine a call center handling customer inquiries for a global brand. The capacity formula acts as the compass, ensuring that the right number of outsourced agents are on hand to handle incoming calls, reducing waiting times, and ensuring customer satisfaction. By calculating the equilibrium between the number of agents, call volume, and customer service goals, the call center achieves a harmonious balance, preventing under-staffing stress or over-staffing redundancy.

How to hire Lean?

Lean manufacturing is the art of producing more with less. The capacity formula is the cornerstone of lean practices, guiding businesses to identify waste, reduce bottlenecks, and maintain flexibility. It’s a philosophy that transforms operations into an agile, adaptable entity. In this case knowing how many SEO executives, media buyers or content writers based on the number of clients you have and not overhiring is the best way to stay ahead.

Demand Forecasting for Marketing Agencies

Predicting the future might be impossible, but demand forecasting gets pretty close. By integrating the capacity formula , operations managers can anticipate fluctuations, preventing shortages or surpluses. This proactive approach keeps businesses ahead of the curve. Specifically for you that means understanding how many employees you need to have to service 1 client while keeping quality high.

By analyzing historical data on customer behavior and preferences, plus local events, a bakery can make sure that shelves are stocked just right, avoiding the frustration of empty trays and the waste of surplus pastries. This foresight ensures customers are delighted while minimizing excess inventory.

In the case of an agency, imagine a new client signs a $15k/month ad management contract. You assign a media buyer who is already at 95% utilization.

• The Result: The media buyer is overburdened, the new client's campaign underperforms, and the client churns in 6 months.

• The Solution: Use the capacity formula to determine the optimal allocation of your experts (media buyers, SEO strategists, content creators). If the formula shows a team member is over-utilized, you must either:

• Automate: Implement an AI workflow (like automated reporting) to free up 5-9 hours per week.

• Hire: Bring in a new resource.

• Decline: Say no to the client until capacity is created.

Advantages and Disadvantages of the Capacity Formula

Pros of Implementing the Capacity Formula

The capacity equation is not a suggestion; it is the operational formula for sustainable, 8-figure growth. If you are constantly firefighting, dealing with high churn, and feeling like you can’t keep up with sales, the math is telling you where to focus. Fix the capacity bottleneck first, and your sales efforts will finally pay off.

Cons of Implementing the Capacity Formula

Change isn’t without challenges. Implementing the capacity formula might require an overhaul of existing processes, which can be met with resistance. Additionally, miscalculations in capacity can lead to under-utilization or over-extension. However, with the right expertise, these obstacles can be overcome.

Mitigating the Disadvantages of Capacity Formula

Mitigating the disadvantages of the capacity formula requires a holistic approach that embraces flexibility and foresight. One key strategy is incorporating contingency plans that account for unexpected fluctuations in demand or resource availability.

Additionally, leveraging advanced analytics and data-driven insights can help organizations make informed decisions, optimizing capacity utilization and minimizing the risk of overextension or underutilization. Through proactive planning and adaptive strategies, businesses can transform potential pitfalls into opportunities for growth and resilience.

This is where the 8 Figure Agency shines. Our services are designed to help agencies navigate the intricacies of capacity planning, operational enhancement, and resource allocation. With our guidance, challenges can be turned into opportunities, ensuring that your agency thrives even in the face of complexity.

AI-Driven Optimization for Capacity Formulas

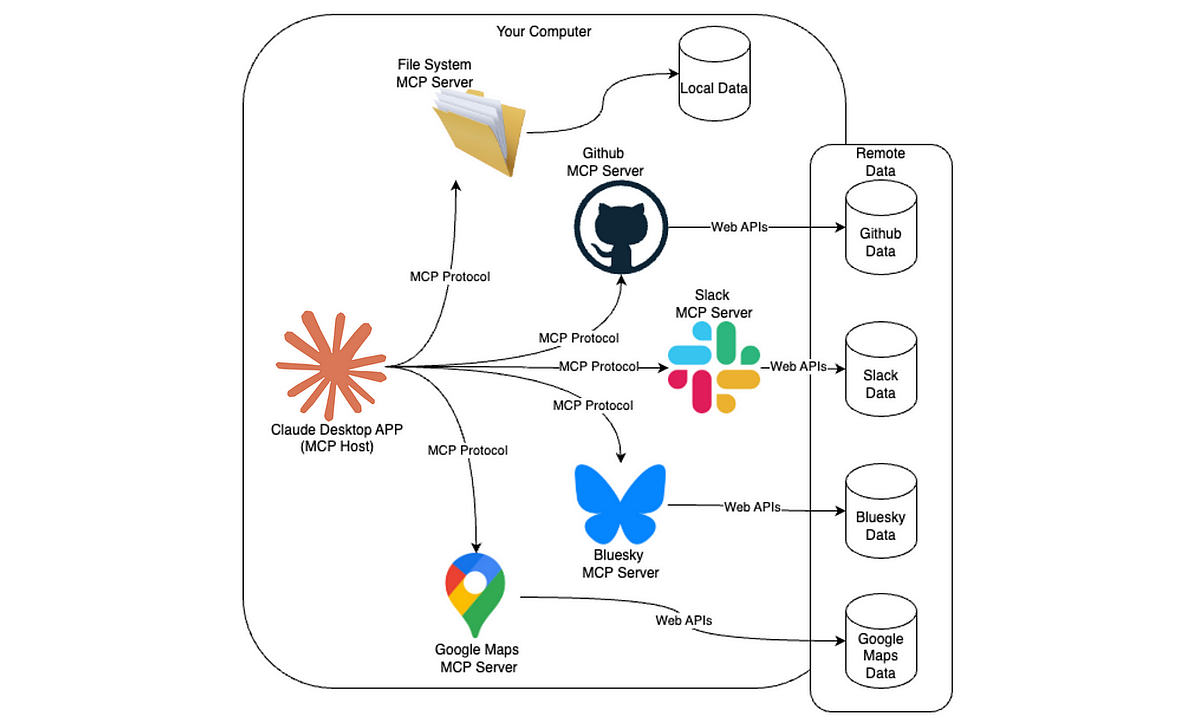

The next evolution of the capacity formula in operations management is powered by AI. We don't just use off-the-shelf tools. We build custom, proprietary AI agents and workflows tailored to your agency's data and processes. This includes:

• The Capacity Agent: A custom AI agent that monitors team utilization in real-time, flagging when a resource is approaching a critical threshold (e.g., 90% utilization) and automatically suggesting task re-allocation or the need for a new hire.

• The MRR Cap Forecaster: An agent that integrates with your CRM and financial data to constantly calculate your MRR Ceiling, giving you a clear, data-driven target for operational improvement.

• The Churn Diagnostician: An agent that analyzes client data (communication frequency, project delays, LTV) to predict churn risk before it happens, allowing your account managers to intervene proactively.

Instead of manually tracking spreadsheets, AI analyzes historical data, seasonality, and industry trends to predict demand fluctuations with greater accuracy than any human. This prevents shortages (under-staffing) or surpluses (over-staffing). AI agents can also monitor team utilization in real-time, flagging when a resource is approaching a critical threshold (e.g., 90% utilization) and automatically suggesting task re-allocation or the need for a new hire. AI can identify waste and inefficiencies in your production processes, guiding you to eliminate bottlenecks and maintain the "lean manufacturing" principle of producing more with less.

Stop Guessing. Start Calculating your Growth.

The capacity formula isn’t stagnant; it evolves with technology. As AI, automation, and data analytics continue to reshape industries, the capacity formula will adapt accordingly. Businesses that embrace these advancements will be better equipped to navigate the ever-changing landscape.

By leveraging AI, businesses can enhance their capacity planning, resource allocation, and demand forecasting. AI-driven insights provide a more accurate understanding of variables, leading to more informed decisions.

At 8 Figure Agency, we help founders install the systems that make capacity scalable. We turn the complexity of the capacity planning formula in BPO into a simple, actionable dashboard that gives you total clarity on what to tackle next.

Ready to get clear on your real bottlenecks and break through your MRR ceiling?

FAQs

What is Capacity Utilization Rate?

The capacity utilization rate measures the extent to which available resources are being used to achieve their full potential. It’s a percentage that reflects how efficiently resources are being employed.

How is Capacity Utilization Calculated?

Capacity utilization is calculated by dividing the actual output produced by the potential output that could be achieved under ideal conditions. The formula is (Actual Output / Potential Output) * 100.

What are the Factors Affecting Capacity?

Capacity is influenced by a variety of factors, including the availability of resources, technological capabilities, market demand, regulatory constraints, and the efficiency of operations.

What is the Role of Capacity Formula in Resource Allocation?

The capacity formula is instrumental in resource allocation by providing insights into how resources can be optimally distributed to achieve maximum productivity. It helps prevent overallocation or underutilization of resources.

Leverage The Capacity Formula For Unprecedented Success

From manufacturing floors to service industries, from project management to the heart of marketing, the capacity formula empowers businesses and agencies to unlock their true potential and achieve unparalleled success.

As industries evolve and challenges emerge, the capacity formula remains a constant guide—a tool that transforms challenges into stepping stones and potential into realized achievement. It’s not just a formula; it’s a mindset that propels businesses toward excellence.

And as you embark on this journey towards operational excellence, remember that you’re not alone. At 8 Figure Agency, we understand the complexities of growth, the nuances of operational enhancement, and the power of streamlined fulfillment processes. Our dedicated team is ready to partner with you, helping your agency ascend to the pinnacle of 8-figure success.

The post The Capacity Formula: Unlocking the Key to Optimal Productivity appeared first on 8 Figure Agency.